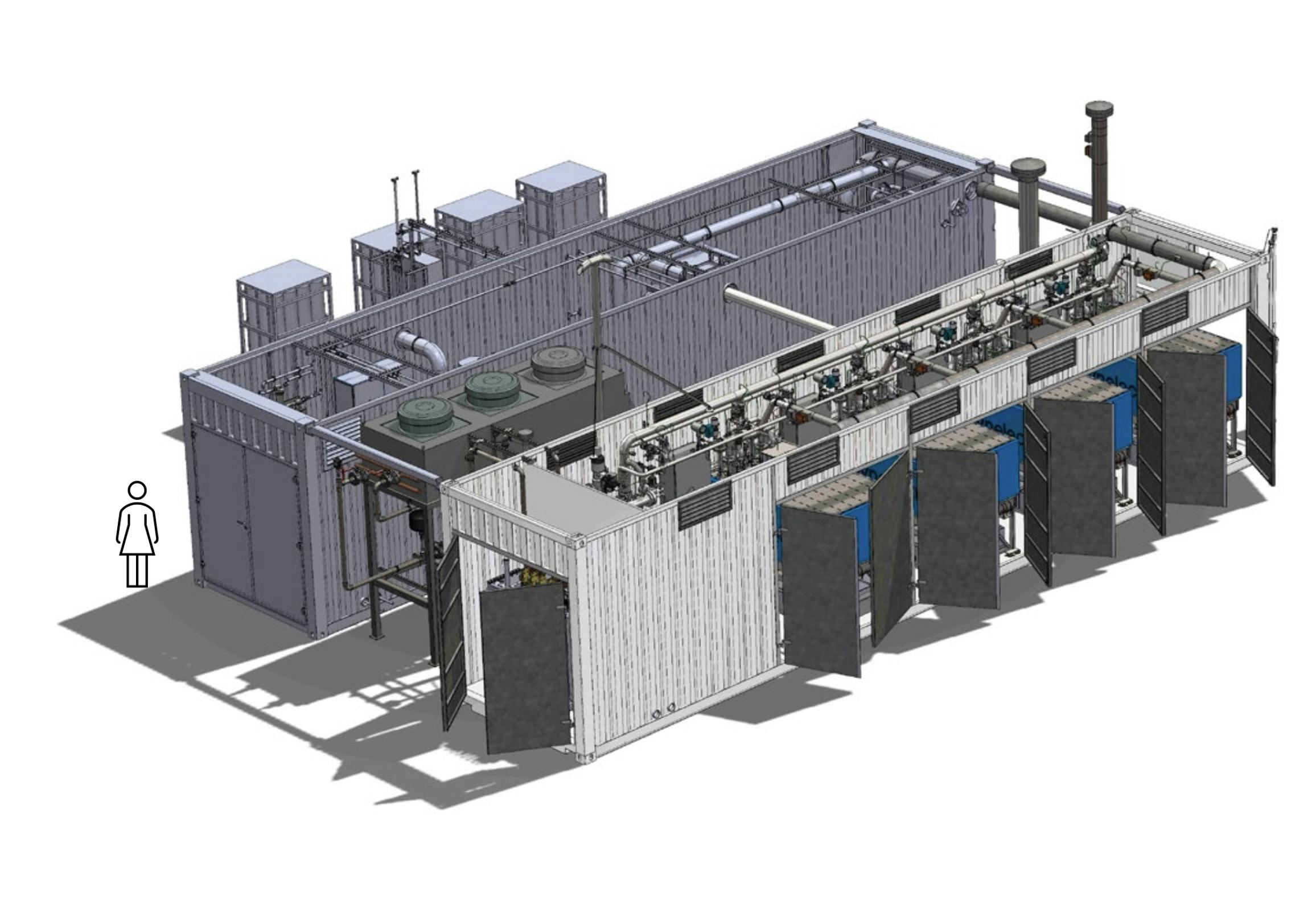

Dynamic Electrolyser Unit – 1 MW

1 MW of SOEC electrolysis capacity, corresponding to 27 kg/h of hydrogen and an electrical efficiency up to 90%

The DynElectro 1 MW SOEC Electrolyser System is a solid oxide electrolyser (SOE) module engineered for industrial-scale hydrogen production. Built on proprietary SOE+ technology, it achieves a 500 % extended stack lifetime through dynamic AC/DC operation and a 20 % reduction in the Levelized Cost of Hydrogen (LCOH).

Engineered with precision

Each 1 MW module is designed for seamless integration into existing industrial plants and scalable installation up to multi-MW configurations.

Documented performance

Tested for 25,000 hours at ultra-low degradation rates (<0.2 % per 1,000 h), DynElectro’s technology delivers proven performance, long-term cost advantages, and a scalable pathway to net-zero industrial operations.

- Low stack degradation – enable 5x SOEC stack lifetime extension due to alternating AC/DC operation – <0.2% stack degradation per 1,000 hours

- Increase H2 output – 50% higher hydrogen output per power unit vs. Alkaline / PEM electrolysis

- Reduced cost – 20% lower LCOH vs. other PtX technologies

- Dynamic operation / Variable Load Following – ideal for fluctuating renewable input

- Ancillary Grid Service offering possible – flexible operation enables availability for FFR / FCR / FRR capacity offerings

Applications

Hydrogen production for:

- Synthetic fuel synthesis (e-fuels, methanol, ammonia)

- Industrial process integration (chemicals, steel, refineries)

- Distributed heat and power applications

Technical Specification:

| ELECTRICAL RATING | |

| Max. System power consumption | 1.1 MW |

| Power consumption (stack) | 33.5 kWh/kg (3 kWh/Nm³) |

| Power consumption (system) | 37.8-40 kWh/kg H₂ (3.4-3.6 kWh/Nm³ H₂) |

| System electrical efficiency with heat integration | ≈ 90% (electrical) |

| System electrical efficiency w/o heat integration | > 70% (electrical) |

| HYDROGEN PRODUCTION | |

| Max. Production rate | Up to 27 kg/h (321 Nm³/h) |

| Operational pressure | 0.025 bar(g) |

| Hydrogen purity (dry) | > 99.99 % |

| Hot start-up time | <10 minutes |

| Dynamic operation | 5-100% load (idle to full load) |

| Dynamic load change response time | < 30 sec (5-100%) |

| WASTE HEAT / STEAM INPUT | |

| Operational pressure | 4.5-6 bar(g) |

| Temperature | 150-200 °C |

| Consumption | 323 kg/h |

| ADDITIONAL SPECIFICATIONS | |

| Ambient temperature | -20 °C to +40 °C |

| Footprint | Approx. 9×21 m |

| Stack lifetime | <0.2 % degradation per 1,000 hours (≈ 10 years) |